TDK’12™ Code

The Two Dimensional Kinetics Program, TDK’12™ is the latest version of the JANNAF standard code for the prediction of nozzle performance in liquid rocket engines. TDK’12™ incorporates the 2008 version of TDK, as well as foreign funded improvements incorporated in TDK’08X™.

TDK’12™ analyzes and summarizes the performance loss mechanisms into four categories:

- Combustion Chamber losses

- Boundary Layer losses

- Chemical Kinetics losses

- Boundary Layer losses

New in TDK’12™

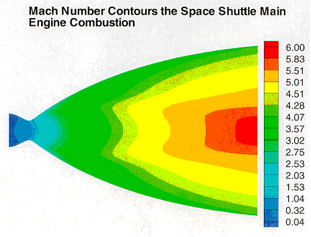

STS Module

A Navier-Stokes chamber and transonic flow field solver with fully coupled finite rate kinetics and several turbulence models. The STS is fully compatible with inflow and wall boundary condition options available to the MOC/chamber flow field option. The STS can be used to model fluid injection at the wall in the subsonic portion of the nozzle.

PNS Module

The PNS module has been linked to the STS Navier-Stokes chamber and transonic flow field solver allowing for fully viscous solutions for the entire nozzle flow. The nozzle wall slot injection capability has been made operational in TDK’12.

Windows Graphical Users Interface

Significant improvements have been made to the Windows User Interface program.

Graphics

Graphical support for both TecPlot™ and ParaView 3-D graphics packages

The TDK’12™ is fast and robust enough to provide performance predictions for extensive parametric studies and sufficiently accurate to provide flowfield and performance solutions for detailed studies.

Features of TDK’12™

Two supersonic flow solvers and two subsonic/transonic solvers:

- MOC - Two-Dimensional Method of Characteristics solution with fully coupled finite rate kinetics.

- PNS - Parabolized Navier-Stokes solver for liquid propellant rocket nozzle performance calculations with fully coupled finite rate kinetics and several turbulence models.

- Navier-Stokes chamber and transonic flow field solver (STS) with fully coupled finite rate kinetics and several turbulence models. The STS is fully compatible with inflow and wall boundary condition options available to the MOC/chamber flow field option.

Models chemical reactions with a generalized reaction package that includes 3rd body efficiencies and four different reaction rate forms.

TDK’12™ optionally performs flow solutions with frozen or equilibrium chemistry (MOC only for equilibrium chemistry).

Provides planar or axially symmetric flow solutions.

Supports both upper and lower wall flow simulations.

Treats planar flow/external flow interactions (MOC only).

Incorporates the mass addition boundary layer, MABL, module, which includes finite rate chemical kinetics. This module optionally performs frozen or equilibrium chemistry (MOC only).

The MABL module treats mass injection at the wall for tangential slot injection or transpiration cooling. The PNS module also treats mass injection at the wall for tangential slot injection.

Improved accuracy and precision from prior versions due to better algorithms and coding changes.

Incorporates a direct search Nozzle Contour Optimization (NCO) module of the MOC which find the best performing skewed parabola nozzle contour including kinetics and boundary layer effects.

MOC treats discrete shocks: attached or induced. The PNS and STS modules have shock capturing capability.

Models equilibrium radiation heat transfer for the wall (incorporated in the MABL Boundary Layer Module or the PNS module).

Models variable mixture ratio profiles from the combustion chamber injector.

Models combustion effects due to injector inefficiencies.

Provides engine performance predictions for axially symmetric nozzles, scarfed nozzles, plug nozzles, and scramjet nozzle configurations (MOC only). The plug nozzle module includes a base pressure correlation.

Improved file handling and error routines; reducing disk space and improves tracking of result files. Includes improved output files; auxiliary ASCII files with tabulated and summary data

Improved user interface for Windows PC users.

Available on Windows and Linux platforms.